IMPORTANT: We highly recommend watching our online installation videos before installing your drain. Visit www.hydroblok.com and click on the YouTube link/logo. Read all related installation guides and ensure you understand all steps before installing your HYDRO-BLOK Shower System. Contact your local HYDRO-BLOK representative or call us at 1-844-588-9559 if you have any questions regarding the installation process.

Before Installing your HYDRO-BLOK Shower System

NOTE: For additional installation options for back wall with hidden drain or curb-less entry at shower entry, see the installation guide included with your ebbe INNI Linear Drain

This installation guide is to be used exclusively for the installation of HYDRO-BLOK Single Slope Shower Pans with an Ebbe America INNI® Linear Drain system.

Surfaces must be structurally sound, stable, rigid, and clean prior to installation. Following TCNA standards for tile installation, the deflection of the substrate must not exceed L/360.

For proper backing support where the drain/shower pan meet your HYDRO-BLOK wallboard, a minimum 2” x 4” bottom plate (1 1/2” high)

must be present. This provides the wallboard with the necessary support needed at the shower pan joint. Add additional backing between the studs if necessary.

Installation Tools and Materials Required

-

Drill/driver with #2 Philips screwdriver bit

-

Tile saw, circular saw, or chop saw to cut drain for site sizing

-

Reciprocating saw or oscillating multi-tool for sub floor prep

-

Tape measure, razor knife, and carpenter pencil or marker

-

Level, straight edge, and square

-

ABS cement or ABS to PVC Transition cement

-

Modified Thinset with 3/8” minimum notch trowel, mixer, bucket and sponge

-

Cleaning supplies (we recommend paper towels, citrus wipes, rags, dust pan and brush)

IMPORTANT: Please read all related installation guides before installing your HYDRO-BLOK Shower System! Contact your local dealer if you have any questions regarding the installation process.

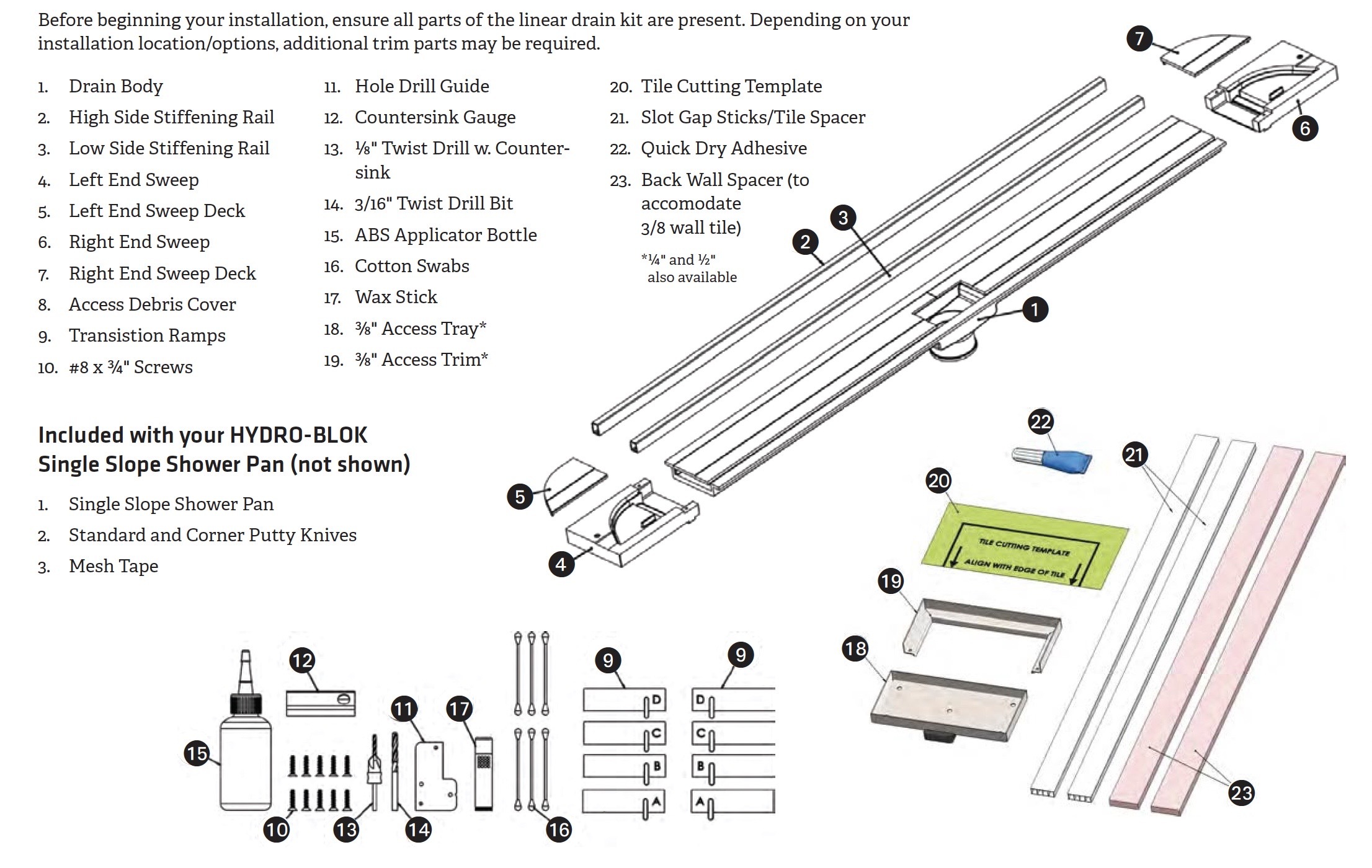

Included with your Ebbe INNI Linear Drain Kit

Before beginning your installation, ensure all parts of the linear drain kit are present. Depending on your installation location/options, additional trim parts may be required.

Before beginning your installation, ensure all parts of the linear drain kit are present. Depending on your installation location/options, additional trim parts may be required.-

Drain Body

-

High Side Stiffening Rail

-

Low Side Stiffening Rail

-

Left End Sweep

-

Left End Sweep Deck

-

Right End Sweep

-

Right End Sweep Deck

-

Access Debris Cover

-

Transistion Ramps

-

#8 x ¾” Screws

-

Hole Drill Guide

-

Countersink Gauge

-

⅛” Twist Drill w. Counter- sink

-

3/16″ Twist Drill Bit

-

ABS Applicator Bottle

-

Cotton Swabs

-

Wax Stick

-

⅜” Access Tray*

-

⅜” Access Trim*

-

Tile Cutting Template

-

Slot Gap Sticks/Tile Spacer

-

Quick Dry Adhesive

-

Back Wall Spacer (to accomodate

3/8 wall tile)

*¼” and ½” also available

0

Included with your HYDRO-BLOK Single Slope Shower Pan (not shown)

-

Single Slope Shower Pan

-

Standard and Corner Putty Knives

-

Mesh Tape 0

-

-

)

)

Positioning the Drain Pipe

Using appropriate tools, remove a 4”x6” section of the subfloor centered around the drain pipe location. Have a qualified plumber install a 2″ ABS drain pipe so that the top of the pipe is 1-1/4″ below the top surface where the drain will be installed.

The drain pipe must be securely fastened below the subfloor so that it will not move down under load. Clean off any burrs on the 2″ pipe after cutting. See specifications for proper placement of the pipe for your application.

Notes

-

Installation to be completed in accordance with manufacturer specifications.

-

Drawings are not to scale.

-

Single Slope Pans are sloped at 1/4” per foot to the drain.

-

Line Drain will attach to pan on thin edge. Underlined dimension in pan part number indicates edge for drain attachment.

HYDRO-BLOK LINE DRAIN STANDARD PLUMBING PREP

Typical Sub-Floor

Typical Stud Framing

Drain pip center based on 1/2” wallboard and 3/8” thick wall tile. Adjust as needed for tile thickness.

Typical Sub-Floor

4” x 6” cut-out in sub-floor to be centered

around drain pipe

HYDRO-BLOK LINE DRAIN PLUMBING PREP AT BACK/SIDE WALL

4” x 6” cut-out in sub-floor to be centered

around drain pipe

![]()

Site Sizing and Assembling the Linear Drain for Installation

The INNI Linear Drain is designed to be cut down to accommodate each specific installation. If your installation requires a Linear Drain that is longer than 73-3/8”, this can be accomplished by using the Line Drain Slot Extender or Line Drain Coupler. Contact your local HYDRO-BLOK representative for assistance or visit www.hydroblok.com for more information on these products.

-

In the shower opening, measure from the center of the drain pipe to each end of the desired drain length. Use a tile saw, circular saw, or chop saw to rough cut each end of the drain body so that it will fit inside the shower opening, leaving approximately 1″ of clearance at each end.

-

To make the final cuts place the Drain body in the desired location. Place the left and right End Caps against the left and right walls respectively. The End Caps will help to determine the final cut length of the Drain Body. Using a square, carefully mark a line on the top of the Drain Body at the location of the upper ledge of the End Cap (fig X). The Drain Body is now ready for the final cut. Ensure all cuts to the Drain Body are NEAT and SQUARE.

Fig. 1

-

Once the final cuts have been made, de-burr the parts with a utility knife and dry fit the Drain Body and End Caps together tightly to verify the assembly fits the desired width with a 1/8” maximum gap on each end.

-

Using the supplied drill jig and countersink bit (fig X), drill two holes at each end of the Drain Body that will align with the screw chases manufactured into the End Cap.

-

Countersink each of the 4 holes using the supplied countersink bit and jig so that the included screws will sit flush with the top of the Drain Body.

-

Each End Cap will come with a cover factory installed. The covers will need to be removed temporarily for the following steps. Remove the covers by gently lifting or prying upward from inside the cavity.

-

On the underside of the Drain Body zones A,B,C, and D are marked in raised lettering. Select the Transition Ramps with the markings matching the zone where the final cut has been made.

-

Each End Caps has a cover support rib. The rib on the Ramp you select needs to align with the deck support ribs built into the Drain Body channel. Dry fit the Ramps into the End Cap and then Drain Body. If the final cut intersects one of these ribs you will need to remove the overhung portion of the Ramp rib so it will not interfere with the main channel rib.

-

Ensure each End Cap is located on the appropriate side of the Drain Body by temporarily placing the End Cap covers in place, ensuring the slot aligns with the slot on the main drain body.

-

On each End Cap, apply a continuous bead of ABS pipe cement as shown (fig X) using the applicator bottle supplied with the Linear Drain kit. Firmly press the matching Ramp insert into place ensuring the rib on the Ramp insert aligns with the rib on the End Cap.

-

Using the supplied applicator bottle, apply 2 continu- ous beads of ABS cement as shown (fig X) to one of the End Caps and immediately fit the End Cap onto the main Drain Body. There should be a sufficient amount of ABS cement applied so that cement squeezes out on the top side.

-

While supporting the joint, install two of the supplied screws to secure the End Cap to the Drain Body. Remove any excess ABS cement squeeze out using the included cotton swabs and/or rags.

-

Flip the drain assembly over and apply an additional heavy bead of ABS cement along the entire seam between the End Cap and Drain Body. Let the Drain sit upside down for approximately 1 minute to allow this bead to set up before flipping back over/continuing.

-

Repeat this step for the second end cap.

-

Install the End Cap Covers by applying a small amount of ABS cement as shown (fig X) and firmly pressing the covers into place.

-

At this stage it is recommended to perform a simple watertight test by plugging the drain connection and filling the linear drain body with water to the top of the Drain. Ensure there are no leaks present at either of the End Cap seams.

Fig. 1

Fig. 1

Fig. 1

Fig. 1

Fig. 1

Fig. 1

Fig. 1

Fig. 1

-

Measure the length of the underside channels on the front and rear of the assembled Drain Body. Mark and cut the two Aluminum Support Rails ¼” less (allowing for 1/8” on each end to avoid the bead of ABS applied to the End Sweep).

-

Dry fit each Support Rail into place, ensuring the slot-side rail (labeled) is placed on the slot side of the Drain Body (labeled).

CAUTION: the two Aluminum Rails are different heights and must be placed on the correct side of the drain body.

Fig. 1

-

Remove the peel and stick backing from the adhesive on each Support rail and press each rail firmly into place.

21. Use the supplied jig as shown (Fig X) and drill 3 holes through the drain body and into the Support Rail along each side; one near each end of the rail, and one in the center. Countersink each hole so that the screw heads will sit flush with the top of the drain body. Install the supplied screws until tight and flush (do not overtighten!).

At this point the drain is completely assembled and you are now ready to proceed with the installation into your shower area.

![]()

Installing the Linear Drain – Typical Back Wall Installation

-

Dry fit the drain assembly into place. Included in the drain kit are 2 Pink ¼” x 1” Foam Filler Spacer Strips. If the selected tile to be installed is a smaller format with a

¼” thick body or less then these will not be used. If the tile is 3/8” thick large format, use the included spacers between the framing and drain body so that after the tile is installed it will flush out with the backside of the Drain Slot.

-

Mark the floor at the front edge of the drain assembly.

-

Using modified thinset, fill in the hollow portion on the underside of the drain end caps.

-

Using a trowel (minimum 3/8” notch), comb the floor in the marked area where the drain sits with modified thinset.

-

If the pink spacer strips are used, apply continuous bead of HYDRO-BLOK Joint Sealant to the Drain Body and adhere them to the Drain, Apply an additional bead of sealant to the framing where the assembly will contact it.

-

Apply ABS cement to the drain connector and pipe, then quickly and firmly set the drain into place, ensuring that the pipe extends all the way into the connector. Pull up on the pipe with your fingers or use a rubber hammer handle angled into the pipe for leverage if necessary.

-

Ensure sure the Drain is level. Shim if necessary.

-

With a sponge, wipe away any visible thinset that may have squeezed out while setting the Drain into place

Fig. 1

Fig. 1

Installing the HYDRO-BLOK Single Slope Shower Pan

-

Measure the remaining space for the Shower Pan. Remem- ber to leave appropriate space to accommodate your HYDRO-BLOK Shower Curb (if applicable). Deduct ¼” overall each in dimension to allow for a 1/8” gap at the perimeter and between parts.

-

Cut the Shower Pan and any Pan Extensions to size using a circular saw. See APPENDIX X for details on how to remanufacture the factory notches on any side where a cut was made.

NOTE: If removing more than 4” on the sloped dimension of theShower Pan, always cut the rear/back/taller side of the pan so that the height of the pan at the drain body remains the same.

-

Dry fit the Shower Pan on the subfloor. Ensure all sides of the Shower Pan fit comfortably with a 1/8” perimeter gap. DO NOT try to force the shower pan into its location. Doing so may damage the pan and prevent proper installation of the wallboard.

-

Dry fit the first row of ½” HYDRO-BLOK Wallboard around the entire perimeter (cut to size using a utility knife with a new blade), beginnig with the back wall at full width followed by the sides. On a typical climate day, the

HYDRO-BLOK Joint Sealant has a ~ 20 minute working time. Having parts pre-cut will allow the Shower Pan and first row of Wallboard to be installed within this time frame. If a HYDRO-BLOK Shower Curb is to be installed, first install the Wallboard as the curb must be installed between Wallboard.

-

Apply a 1/2” bead of HYDRO-BLOK Joint Sealant along the entire length of the Drain body at the subfloor and another bead near the top edge. Apply modified thinset (minimum 3/8” trowel) to the entire subfloor (DO NOT apply thinset within 1” of the Drain body/Joint sealant). Trowel marks should be straight and running perpendicular to the Drain Body to allow air to escape when setting the Shower Pan into place.

-

Place the lower front edge of the Shower Pan onto the subfloor at the Drain between the Joint Sealant and the thinset. Slowly lower the back of the Shower Pan into place while applying pressure in the direction of the Drain Body and compress the parts together. A bead of Joint Sealant should squeeze out between the Shower Pan and Drain Body.

-

Carefully stand/walk on the Shower Pan to embed it into the thinset and make any necessary adjustments to center the Shower Pan in the opening. Use a level to check the slope. Wipe away any excess thinset in the perimeter Shower Pan channel or at the Shower Curb area with a sponge.

-

Use masking tape or duct tape to mask off the entire Drain Slot opening to prevent Joint Sealant from entering the Drain channel. Apply the tape so that from the Shower Pan side, it barely catches the surface on the backside of the slot and at both ends. It is necessary to leave as much of the flat top surface of the drain exposed in these locations to allow for Joint Sealant and Mesh Tape in the following steps. DO NOT tape over the exposed screws. They must be complete- ly covered with Joint Sealant during the following installation steps for HYDRO-BLOK Wallboard.

Fig. 1

Fig. 1

Fig. 1

Installing HYDRO-BLOK Wallboard

-

Apply a 1/2” continuous bead of Joint Sealant inside the perimeter channel created by the Shower Pan at the wall plate. Place the rear Wallboard into the channel and firmly compress the lower edge into the bead of Joint Sealant. Use a level and tape measure to ensure the board is properly seated to within 1/8” of the depth of the channel.

-

Fasten the Wallboard to the studs using HYDRO-BLOK Screws and Washers. Place the first Washers 12″ up from the bottom of the Shower Pan, then every 12” vertically on minimum 16” stud centers. Drive the Screws/Washers in flush or just past flush to the surface of the Wallboard.

NOTE: Any Screws/Washers that land on a seam with another Wallboard can span the boards, so only 1 is required at these locations (including intersections).

-

Use the HYDRO-BLOK corner putty knife to smooth out the excess Joint Sealant from the seam between the Pan and Wallboard. Any excess Sealant removed can be used to fully cover any Screws/Washers.

NOTE: Continue installing the first row of Wallboard and then finish the Shower Pan to Wallboard connection (Steps X to X below).

-

Apply a ½” continuous bead of Joint Sealant in the Shower Pan channel on the side at the bottom plate and another bead running vertically on the end Wallboard so that when installing the side Wallboard it can be pressed firmly into the Shower Pan channel and against the rear Wallboard creating a bond and seal. Place the side Wallboard approximately 1” from the rear Wallboard and compress it into the shower pan channel and towards the rear Wallboard until seated. Use a level and tape measure ensure it is properly set into place.

-

Attach the Wallboard to the studs with Screws and Washers and tool the Shower Pan to Wallboard joint using the same method described in STEP 11. Continue this process until the first row of Wallboard is installed.

Fig. 1

-

To finish the joint and seam connections between the Shower Pan and Wallboard, apply a final bead of ½” joint sealant on all joints and seams and smooth out with the included putty

Fig. 1

Fig. 1

Fig. 1

knives. Use a HYDRO-BLOK corner putty knife for all 90 degree joints and the standard putty knife for all flat seams. Ensure there is at least 1″ of joint sealant on either side of any joint or seam. Excess sealant can be used to cover Screws/Washers.

-

Cut lengths of the supplied 2” mesh tape to cover all joints and seams between the Shower Pan, Drain Body, and Wallboard. Lengths should be cut to within approximately 3” of the corners. It is not required to install the mesh tape all the way to the corner, or up vertical joints or seams. When applying to the back side of the Linear Drain Body, install the mesh tape so that it laps down on top of the Drain but not onto the masking tape.

-

Press the mesh tape into the existing joint sealant working from the center out, smoothing any wrinkles flat. Apply another continuous ½” bead of joint sealant on top of the mesh tape and smooth out again with the putty knifes so that the mesh tape is fully covered. Use excess Joint Sealant from this process to cover Screws and Washers.

-

Remove the masking tape from the Drain slot before the Joint Sealant cures. Allow any excess Joint Sealant that entered the Drain Slot to cure, cleaning it out at a later time.

Fig. 1

Installing HYDRO-BLOK Wallboard (cont.)

-

When placing a new piece of Wallboard on top of an existing board, apply a ½” bead of joint sealant along the entire edge of the lower board. Press the new Wallboard firmly down into the Joint Sealant and hold it against the studs while installing a Washer and Screw (12″ up from the seam close to the to center of the board) to provide initial support. If the upper Wallboard is connecting to another previously installed Wallboard at the corner, first apply a ½” continuous bead of Joint Sealant to the existing board vertically at the corner as well and press the Wallboard being installed into the bottom and side beads of sealant at the same time.

-

Install Washers and Screws along the seam at the stud locations and at 12″ vertical intervals to secure the board to the studs. Use a HYDRO-BLOK standard putty knife to smooth out excess Joint Sealant along the seam, using it to cover the seam as well as the Screws and Washers. Ensure all seams have a minimum of 1″ of Joint Sealant on each side of the seam. Apply additional Joint Sealant as necessary

-

To finish the joint and seam connections, apply a final bead of

½” joint sealant on all joints and seams. Use a HYDRO-BLOK corner putty knife for all 90 degree joints and the standard putty knife for all flat seams. Ensure there is at least 1″ of joint sealant on either side of any joint or seam. Excess sealant can be used to cover any Screws/Washers still exposed.

-

Perform a final check of all joints and screws/washers to ensure they are completely covered in joint sealant.

![]()

INSTALLING A HYDRO-BLOK SHOWER CURB

-

If a HYDRO-BLOK Shower Curb is to be installed, measure the opening between the Wallboard faces and cut the Shower Curb 1/8” less. The Shower Curb may be cut with a wet saw, chop saw, circular saw, or hand saw. Ensure that all cuts are square and neat.

-

Apply modified thinset to the floor where the Shower Curb sits (minimum 3/8” trowel), keeping it ½” away from the foam edge of the Pan. Using the flat side of the trowel, coat the exposed foam on the bottom of the Shower Curb with thinset.

-

Apply a ½” continuous bead of Joint Sealant to the Shower Pan notch and on the lower vertical Shower Pan perimeter surface.

-

Apply a generous amount of Joint Sealant to the Wallboard where the Curb will be located and each end of the Curb.

-

Fully compress the Shower Curb into it’s seated position an angle to avoid mixing the thinset and Joint Sealant. Once placed, use a level or square to put a slight angle to allow water to easily drain to the inside of the shower.

-

Use the HYDRO-BLOK corner putty knife to smooth out the excess Joint Sealant from the seam between the Shower Pan and Curb and install 2” mesh tape as described previously. Place an additional small piece of mesh tape at the top of Shower Curb to Wallboard joint. Any excess Sealant can be spread to cover any Screws/Washers remaining uncovered.

HYDRO-BLOK Joint Sealant will cure under water so the shower area may be immediately filled for flood testing. After approximately one hour at room temperature the Joint Sealant will skin over and thinset can safely be applied.

Fig. 1

Fig. 1

Fig. 1

Fig. 1

Fig. 1

APPENDIX X – REMANUFACTURING THE FACTORY SINGLE SLOPE NOTCHES

-

Using a circular saw with a standard wood blade, set the blade depth to 1/8” and make a cut through the cement surface on the top of the Shower Pan ½” in from the new edge.

-

Use a circular saw or utility knife and a straight edge/guide to make a ½” deep cut through the foam on the edge of the Shower Pan, 1″ up from the bottom of the Pan.

-

Use a utility knife to continue cutting the depth through the saw kerf on the slope of the Shower Pan to meet the cut made on the edge of the pan to complete the notch.

![]()

APPENDIX X – INSTALLING THE ACCESS TRAY COVER

-

The Linear Drain Access Cover consists of 2 pieces, the Access Trim and the Access Tray. The Access Trim will be permanently bonded to the Drain body using the supplied tube of fast set glue or HYDRO-BLOK Joint Sealant. The Access Tray does not get bonded to the Access Trim as it needs to be removeable to service the drain. Once the Access Cover assembly is properly installed, it can be removed by using a flat screwdriver or similar tool to push down on that black tab that is visible in the drain slot.

-

Insert the Gap Sticks included with your drain kit. The Gap Sticks aid the tile installation allowing you to complete the process including grout, while maintaining the proper gap width and keeping the slot free of debris when removed. Cut the Gap Sticks to length to fill the entire Drain slot. Use the supplied tube of ebbe wax to coat both sides of the Gap Sticks and insert them into the Drain slot. Continue your tile installation. NOTE: The Drain slot after tiling should not be narrower than the Gap Sticks in order to allow for proper drainage.

-

Cut the tile tight to the Access Trim during installation. Use the supplied template to adhere to the tile for a precise cut location/fit.

-

Cut a piece of tile for the Access Cover. Insert and adhere the tile into the Access Tray with Joint Sealant or thinset. Use the supplied template to adhere to the tile for a precise cut location.

NOTE: DO NOT grout the Access Trim and Access Tray together.

![]()

APPENDIX X – INSTALLATION REQUIREMENTS FOR MOSAIC TILE ON THE PAN

When installing tile or stone that is smaller than 2”x2”, a high performance grout with a minimum 3500 PSI compres- sive strength and meeting ANSI 118.7 or epoxy grout 118.3 must be used to comply with the HYDRO-BLOK warranty. These products are commonly used and readily available.

Fig. 1

Fig. 1

Fig. 1

Share This Article

Choose Your Platform: